April 20, 2022

Boulder, Colorado - April 20, 2022 - PRESSADVANTAGE -

Surna Cultivation Technologies, an MEP engineering company based in Boulder, Colorado, recently provided cannabis cultivation facilities and grow operations a resource for guidance on grow room sizing and specifications.

In their resource titled, "Size Matters: Grow Room HVAC Sizing and Costs," Surna outlines some of the most common requirements for different types of indoor agriculture HVAC. Surna also notes that, while it may be tempting to cut corners to reduce cost, it can lead to significant and more costly problems later.

The goal of an HVAC system is to maintain temperature and humidity levels within a set range. Surna noted that "when building an indoor farm, one of the most important factors to consider is the size of the grow room and overall square footage, as this will affect overall HVAC system expenditures." As indoor cultivation operations grow, the upfront cost for HVAC systems may increase based on the type of system used.

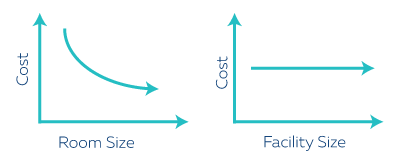

According to Surna, "We've prepared some graphs to help indoor agriculture growers how the cost per ton of common HVAC approaches varies depending on the size of the room and the total square footage of the facility. While we couldn't begin to describe all of the elements that influence the responses to those questions, ranging from budget to lighting load to cultivation style to broader market aims."

The resources created by Surna are a graphical representation of the differences between VRF/VRV systems, DX units, and Chilled Water Systems (2 Pipe and 4 Pipe systems). In Variable Refrigerant Flow (VRF) and Variable Refrigerant Volume (VRV) systems, costs have a linear correlation to the facility size. In contrast, the cost of both integrated package DX units and chilled water systems is reduced per ton as the facility size increases.

"It's important to talk about your project requirements with someone experienced with the nuances of indoor growing," Surna commented. "You want to make sure that your HVAC system is sized correctly for both the heat and light loads of your operation and the humidity control needs of your particular grow."

For more information, interested parties should contact Surna Cultivation Technologies via their website or social media profiles, such as Twitter, Instagram, or Facebook.

###

For more information about Surna Cultivation Technologies, contact the company here:

Surna Cultivation Technologies

Jamie English

(303) 993-5271

jamie.english@surna.com

385 S. Pierce Avenue, Ste. C

Louisville, CO 80027