August 05, 2022

Boulder, Colorado - August 05, 2022 - PRESSADVANTAGE -

Surna Cultivation Technologies is an indoor cultivation equipment and service company that specializes in helping growers build and operate state-of-the-art, energy-efficient, and sustainable indoor cannabis farms.

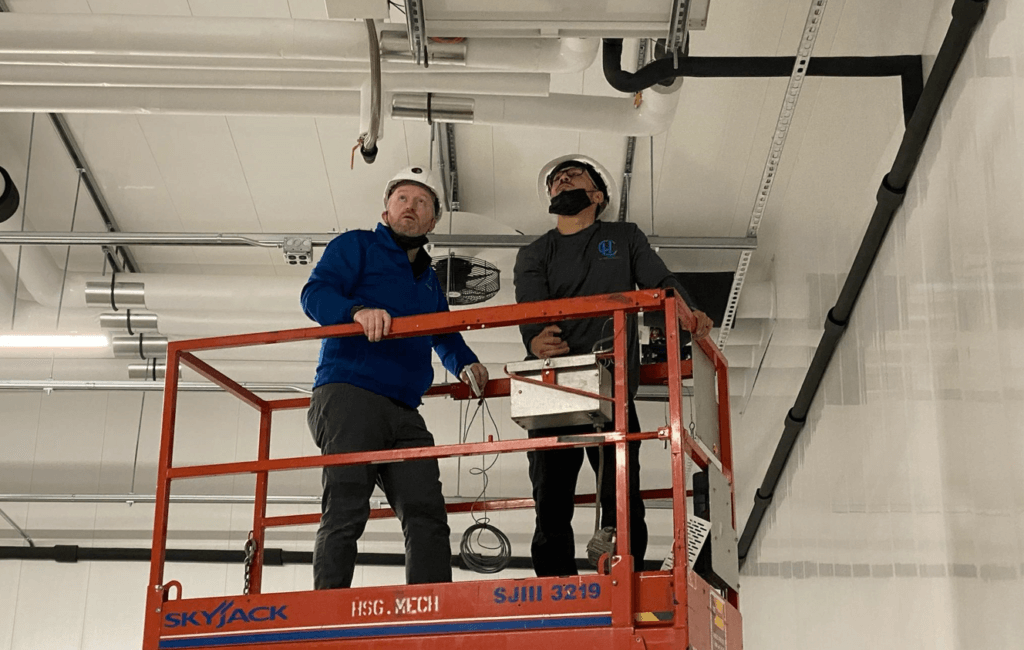

One of the company's core offerings is its HVAC equipment, which is designed to minimize energy consumption while providing optimal growing conditions for plants. In addition to HVAC equipment, Surna also offers MEP (mechanical, electrical, and plumbing) engineering services to help growers plan and execute their indoor cannabis cultivation projects.

Surna has published content about how MEP retrofitting can be used in Controlled Environment Agriculture (CEA). The MEP Retrofitting process for Controlled Environment Agriculture is complex and Surna's goal is to demystify the process and provide readers with clear, concise information.

The experts at Surna highlighted, "Retrofitting means to take something that exists and to renovate or upgrade it for a new application or a new standard of functionality. For controlled environment agriculture (CEA), this implies taking an existing building, and upgrading its mechanical, electrical, and plumbing (MEP) system to be suitable for indoor farming."

"Growing plants indoors requires lighting, HVAC equipment, and other systems that consume electricity. The process of supplying light and watering plants creates a warm and humid climate that must be carefully managed. This combination of requirements makes MEP engineering for indoor ag incredibly unique."

There are several factors to consider when retrofitting a building's MEP systems for cultivation. The retrofit must be designed to accommodate the specific needs of the cultivation process, including structure, electrical, and plumbing. The lighting system must also be appropriate for the type of plants being cultivated. Furthermore, the layout of the cultivation area must be designed to maximize efficiency and yield.

Electrical engineers will assess the site to ensure it has an adequate power supply and that the wiring is up to code. Knowing which equipment will be used – including HVAC and lighting systems – will help them more accurately determine the facility's electrical needs. If retrofitting an existing building that was previously used for other purposes, major electrical changes, including power upgrades, will almost certainly be required. For updating a facility that has already been used for cultivation, the electrical upgrades will be less intense, but will still need to be addressed.

When considering retrofitting an indoor grow, it's important to choose the right MEP engineer. Surna added, "You should carefully vet your MEP engineer if you are considering a retrofit. Ensure they have a successful experience on other CEA projects, and that they can provide stamped construction documents in the location in which you plan to build. Speak to and obtain proposals from multiple providers to compare and contrast not just cost, but the depth and breadth of the engineering scope and support being offered. As a reputable leader in the cannabis and indoor food production spaces, we advocate for growers to seek out proposals from more than one potential vendor. This will allow you to compare your options and feel confident when you find the right fit."

With a team of experienced MEP professionals, Surna is well-positioned to help growers successfully navigate the complexities of indoor cannabis cultivation.

If growers are ready to discuss an MEP retrofit with an engineer, visit Surna's website (www.surna.com). They'll be able to discuss options and help growers choose the best course of action.

###

For more information about Surna Cultivation Technologies, contact the company here:

Surna Cultivation Technologies

Jamie English

(303) 993-5271

jamie.english@surna.com

385 S. Pierce Avenue, Ste. C

Louisville, CO 80027